The onshore and offshore wind sector continues to grow rapidly throughout Asia and ensuring optimal efficiency requires a methodical approach to inspection and ongoing condition monitoring to reduce the risk of costly repairs or catastrophic failure. K2 has a range of inspection and condition monitoring capabilities to suit OEM, operators, and utility companies regardless of the location or size of their fleet.

Inspection and compliance

Visual Inspection and Non-Destructive Testing (NDT)

K2 provides a comprehensive range of inspection and NDT testing to support planned maintenance and end of warranty inspections.

Our services include:

- Close visual inspection using trained and qualified IRATA rope access technicians

- Quality inspections and damage assessments

- End of warranty inspections

- Inspection of lightning protection systems

- Phased array ultrasonic testing (PAUT) and NDT services

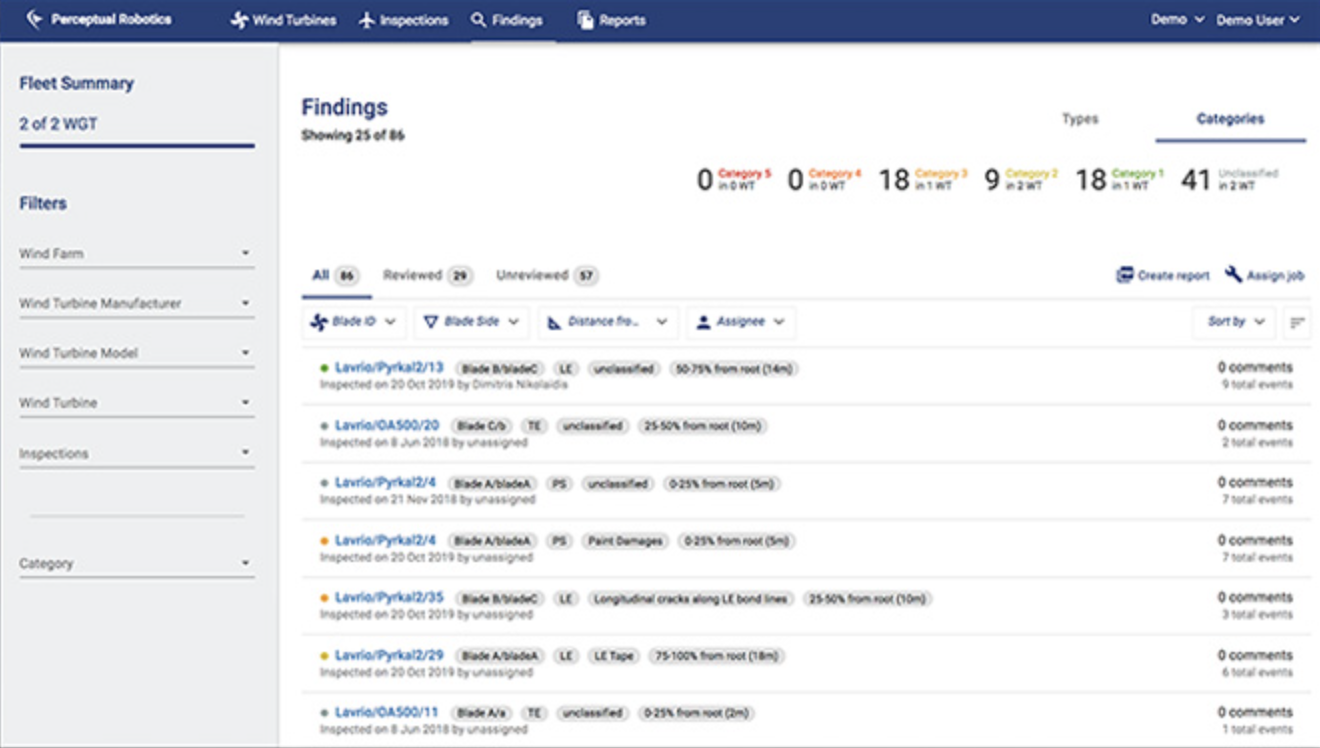

All inspection results are reported through our web-based reporting portal, allowing our customers to view the finding 24/7. When you require a close tactile visual inspection there is no better way than utilising K2’s rope access inspection teams.

Drone inspection

K2 has a range of drones and expert pilots conveniently located throughout Asia that can fulfil detailed video and digital photography inspections on any type of turbine regardless of its location.

Drone inspection is nothing new but the success and effectiveness lies within the capability of the pilot and the collection and interpretation of the data. At K2 we have trained, qualified and experienced pilots supported by blade repair experts who produce accurate and details reports that are hosted on our web based reporting portal.

Total fleet integrity management

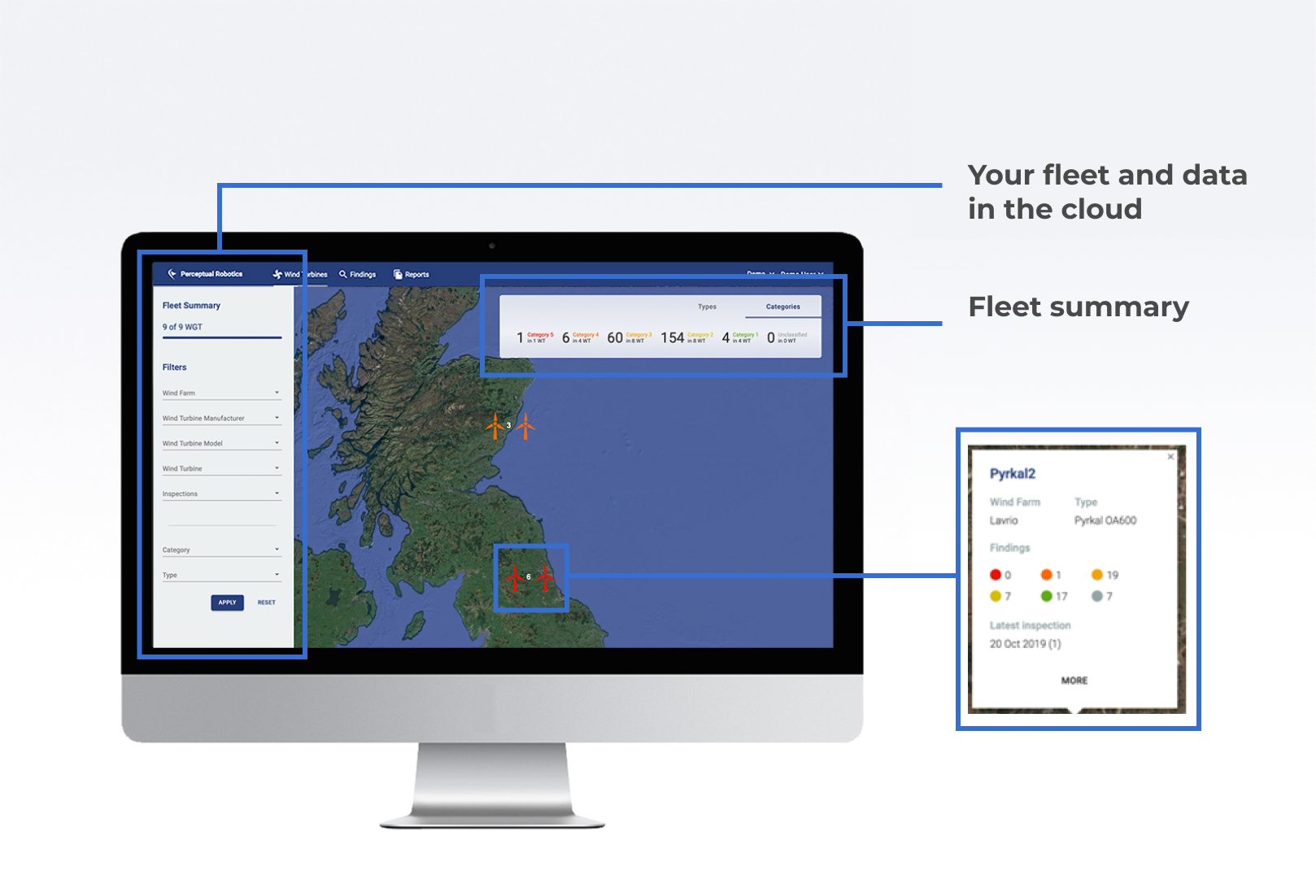

In 2022 K2 Energy Group partnered with Perceptual Robotics an automated drone inspection, analysis and data management company based in Bristol UK.

Our partnership covers Southeast Asia and leverages our regional footprint and existing capabilities to provide a complete integrity management solution for owners and operators of onshore and offshore wind turbines.

Through a technical support and licensing agreement K2 is integrated to the Perceptual Robotics technical team that covers all aspects of the inspection process, data management, reporting and analysis.

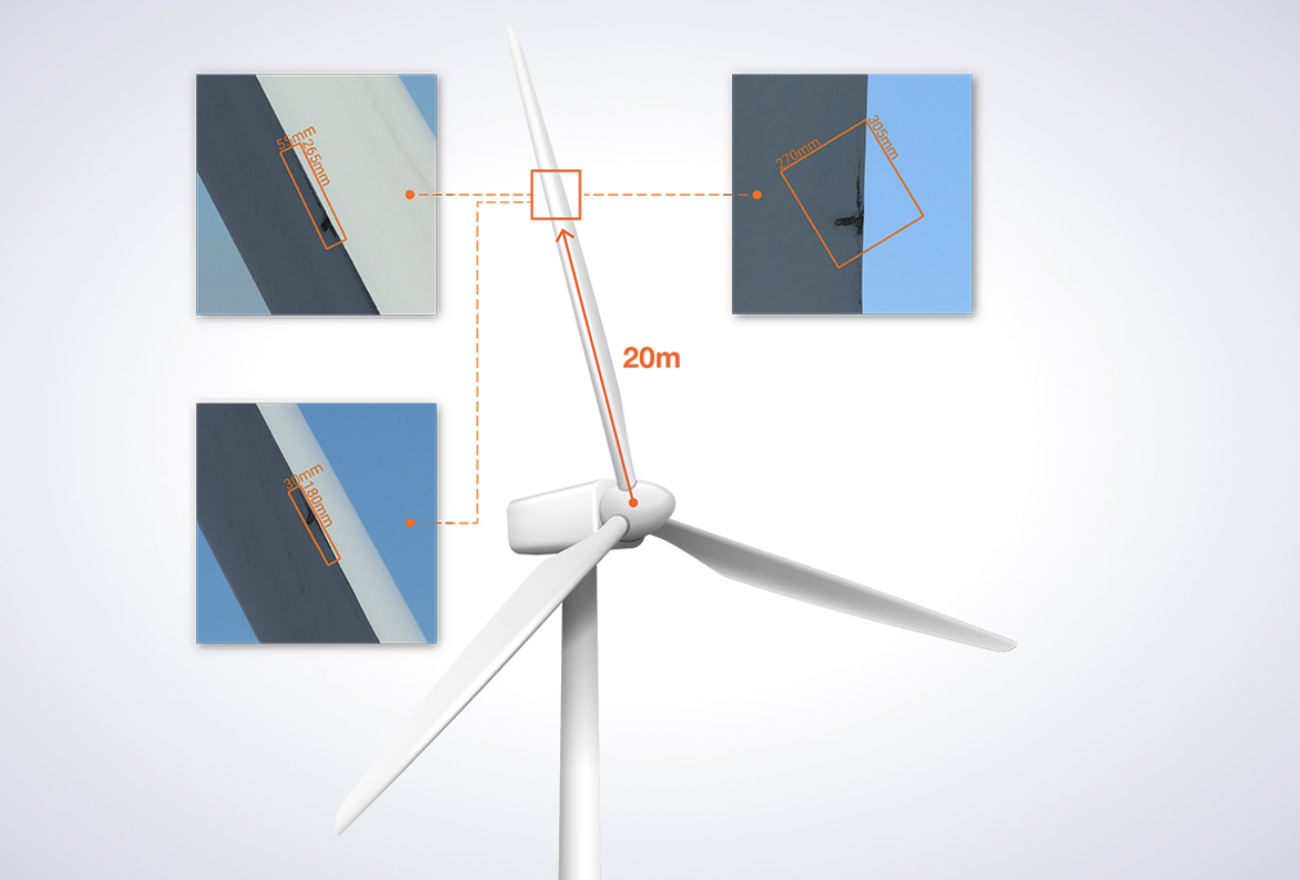

Perceptual Robotics’ autonomous drones inspect massive structures in minutes, performing repeatable data acquisition for high quality predictive analysis, and providing huge cost reductions.

Inspection and data management overview

Integrating robotics, artificial intelligence & cloud technologies

Autonomous drone collects and analyses data

Uploading into the data management platform

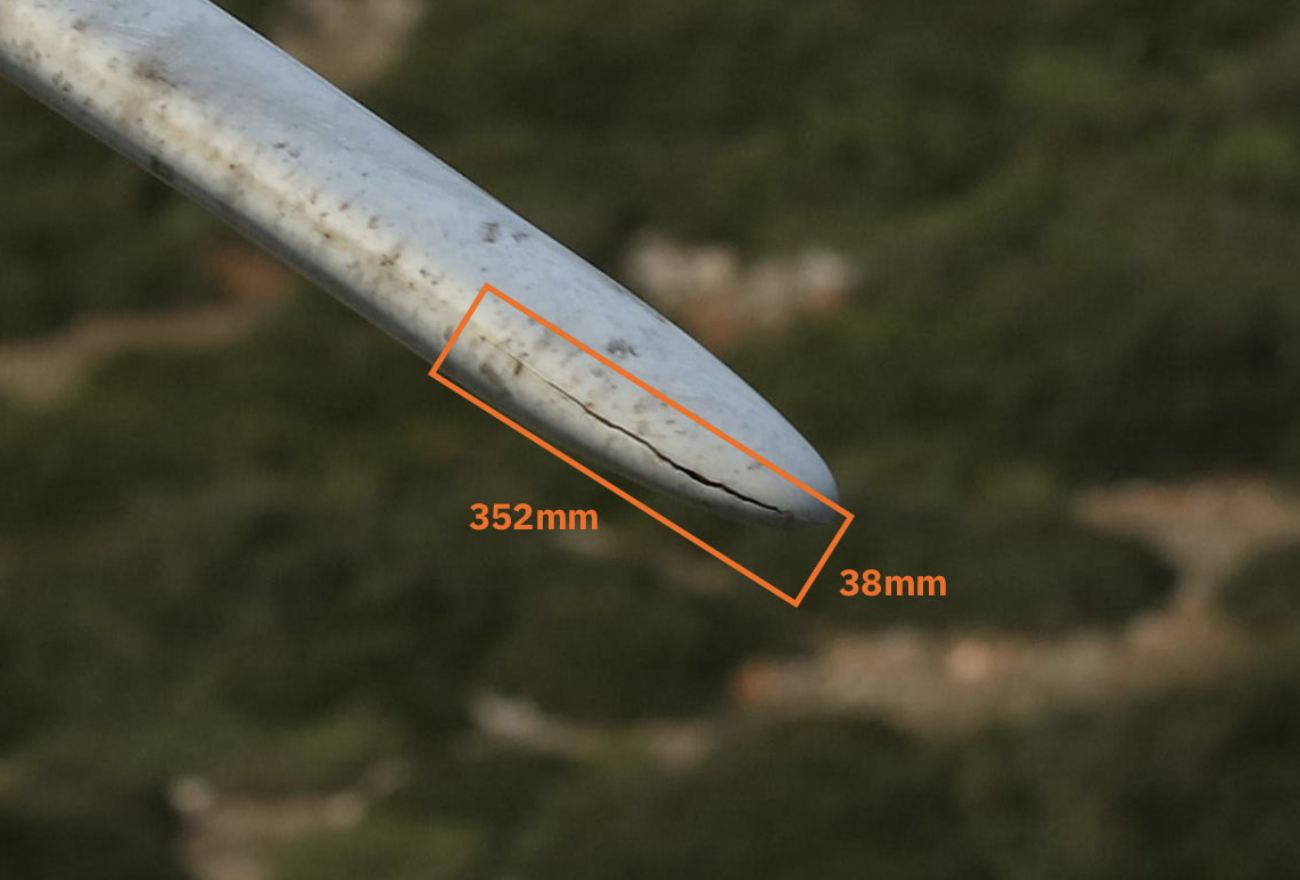

Data processing with AI technology to identify and record anomalies

Inspection Report and Annotated and Categorised data can be delivered in less than 2 hours.

The process is accelerated using a combination of machine learning, image processing and the input of a trained blade specialist.

AI data processing platform

Optimal combination of Machine Learning/ Artificial Intelligence algorithms, image processing and the input of trained blade specialists.

Maximum Flexibility regarding Input and Output formats

- Less time, more efficiency

- Consistency

- Less damages missed

- Integration of all fleet inspections